Possibly you may be interested

- On Sale

- Bestsellers

- Newest

- Most Popular

Gift Ideas!

Brokerage

- Chartplotters

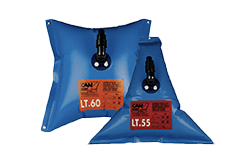

- Inflatable Dinghies

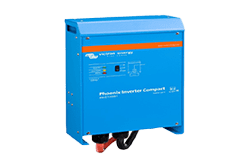

- Batteries & Inverters

- Radios

Chartplotters

About company

topRik is a nautical marketplace startup. We are dedicated to making it easier for yacht owners and enthusiasts to find the right products and services for their needs. Our mission is to provide our customers with innovative, robust, high-quality solutions that meet their needs while providing a safe and reliable experience. We strive to create a platform enabling our customers to access the latest technologies, experiences, and practical solutions in one place while helping them make informed decisions.